Learning Basics of PCBA (Printed Circuit Board Assembly) & more

In the present tech-driven world, understanding the intricacies of printed circuit boards (PCBs) and PCB assembly or PCBA is like holding the key to a complex puzzle. Whether you are a budding engineer, a hobbyist, or simply curious about how the technology in your everyday devices works, learning about PCB and PCBA basics is your gateway to innovation.

What is a PCB?

Before we dive into the assembly process, it’s essential to understand what a printed circuit board (PCB) is. At its core, a PCB is a platform that connects electronic components. It serves as the backbone of most electronic devices, providing mechanical support and electrical connections.

A typical PCB consists of multiple layers, including a substrate, copper layer, solder mask, and silkscreen. The substrate is often made of fiberglass, offering durability and insulation. Copper layers are etched to create pathways for electrical currents, while the solder mask prevents shorts by insulating the copper traces. Finally, the silkscreen layer displays labels and markings for easier assembly and troubleshooting.

PCBs are classified based on their layers and flexibility. Single-layer PCBs are the most basic and are commonly used in simple devices. Multi-layer PCBs, with more than two layers, are ideal for complex electronics like computers and smartphones. Flexible PCBs, on the other hand, bend to fit unique spaces, making them suitable for wearable tech and medical devices.

Knowing the Basics of Printed Circuit Board Assembly or PCBA

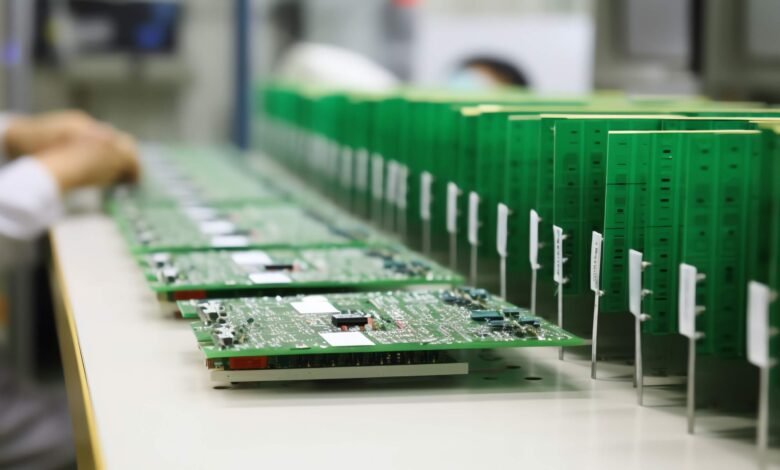

Printed Circuit Board Assembly (PCBA) is the process of soldering electronic components onto a PCB. This involves a combination of manual and automated techniques to ensure precision and efficiency.

The first step in PCB assembly is applying solder paste. This paste, a mixture of tiny metal balls and flux, is applied to the board using a stencil. The paste adheres to areas where components will be mounted. Once the paste is in place, a pick-and-place machine positions components onto the board. These machines are incredibly accurate, capable of placing thousands of components per hour.

Next comes the reflow soldering process, where the board is heated in a reflow oven. This melts the solder paste, forming solid connections between components and the board. After cooling, the board undergoes inspection to ensure all components are correctly placed and soldered. This step is crucial, as it identifies any defects or errors that could impact device functionality.

Another method of assembly is wave soldering, primarily used for through-hole components. The PCB passes over a wave of molten solder, which forms connections with component leads. This method is less common in modern manufacturing due to the rise of surface-mount technology, but it’s still valuable for specific applications.

Finding the right PCBA provider

Evaluating the Technical Capabilities of PCB Assembly Providers

Technical capabilities are at the core of any PCB assembly provider’s offering. Assess the provider’s equipment and technology to ensure they can handle your project’s complexity. Advanced machinery and up-to-date technology contribute to precise assembly and higher quality products.

The ability to accommodate various PCB types and technologies is also crucial. Whether you need single-layer, multilayer, or flexible PCBs, your provider should have the expertise and resources to deliver. Specialized requirements, such as high-frequency PCBs or those with unique materials, require specific capabilities that not all providers possess.

Testing and validation processes are another aspect to consider. A reputable provider conducts thorough testing to identify and rectify any defects before the product reaches the customer. Functional testing, in-circuit testing, and environmental stress testing are examples of procedures that ensure the final product meets specifications and performs reliably.

Assessing the Scalability and Capacity of PCB Assembly Providers

Scalability is a key consideration, especially for businesses with growth ambitions. Your chosen provider should be able to handle increased production volumes without compromising quality or timelines. Providers with flexible production lines and the ability to scale up operations are better equipped to support your business’s evolving needs.

Capacity goes hand in hand with scalability. Evaluate the provider’s current workload and capacity to determine if they can accommodate your production requirements. Overburdened providers may struggle to meet deadlines, leading to delays and potential disruptions to your supply chain.

Lead times are another critical factor. Discuss production schedules and delivery timelines with potential providers to ensure alignment with your project’s demands. A provider with efficient processes and realistic lead times can significantly enhance your project’s overall success.

Navigating the Cost Considerations of PCB Assembly Partnerships

Cost is a significant factor in choosing a PCB assembly provider, but it’s important to consider the bigger picture. While competitive pricing is desirable, it shouldn’t come at the expense of quality or reliability. Analyze quotes carefully, and ask for detailed breakdowns of costs to understand what you’re paying for.

Hidden costs can arise from unexpected delays, rework due to poor quality, or inadequate testing. A provider with transparent pricing and a clear outline of their services helps prevent surprises down the road. Additionally, consider the long-term value a provider brings, such as reduced defect rates or faster time-to-market, which can outweigh initial cost savings.

Negotiating pricing with a potential provider is common practice. Be open about your budget constraints and seek providers willing to offer flexible solutions. Building a strong relationship based on trust and mutual benefit can lead to favorable terms and ongoing cost savings.

Analyzing the Reputation and References of PCB Assembly Providers

A provider’s reputation speaks volumes about their reliability and performance. Research online reviews, testimonials, and case studies to gauge the experiences of other clients! Positive feedback from reputable sources adds credibility and reassures you of the provider’s capabilities.

Request references from the provider and take the opportunity to speak directly with past or current clients. Ask about their experiences, challenges faced, and how the provider addressed them. This firsthand insight can provide a clearer picture of what to expect from the partnership.

Trust your instincts when evaluating a provider’s reputation. If something feels off or there’s a lack of transparency, it may be wise to explore other options. A trustworthy provider values their reputation and is committed to maintaining positive relationships with their clients.

Building a Collaborative Partnership with Your PCB Assembly Provider

Successful PCBA partnerships are built on collaboration and mutual understanding. Clearly define your project goals, requirements, and expectations from the outset. A provider that actively listens and engages with your needs is more likely to deliver results that align with your vision.

Regular communication is essential throughout the project’s lifecycle. Schedule frequent check-ins and updates to stay informed about progress and address any potential issues early. Effective communication fosters transparency and prevents misunderstandings that could impact project outcomes.

Consider your PCB assembly provider as an extension of your team. Involve them in discussions about product design and development to leverage their expertise and insights. A collaborative approach enhances innovation, reduces risks, and leads to higher-quality products.

Ensuring Compliance and Quality Standards in PCB Assembly

Compliance with industry standards and regulations is non-negotiable when selecting a PCBA provider. Ensure that the provider adheres to relevant standards such as IPC, RoHS, and ISO, depending on your industry and requirements. Compliance demonstrates a commitment to quality and safety.

Quality control measures are equally important. Inquire about the provider’s testing protocols and quality certifications. A provider that invests in quality assurance minimizes the risk of defects, recalls, and customer dissatisfaction.

Regular audits and inspections further validate a provider’s commitment to quality. Consider working with a provider that welcomes third-party assessments to ensure transparency and accountability.

Final Thoughts

Understanding the basics of printed circuit board assembly or PCBA unveils the remarkable synergy between design, engineering, and technology. PCBs are the heart of our digital age, seamlessly integrating into devices that shape our daily lives. From smartphones to smartwatches, they power innovation across industries.

Remember, every expert was once a beginner. Delve into the world of PCBs with curiosity and determination, and watch as your understanding transforms into expertise. Your next big idea might be just one circuit away from becoming reality with having a reputable PCB assembly provider at your side.